RECLAIMED WOOD ORDER PROCESS

You choose the wood specie, the size and the look you would like to achieve.

Wherever you see a knot, a branch once grew. Nails, nail holes, saw and plane marks attest to the countless, nameless craftsmen who built this country from the ground up, one barn and homestead at a time. These are barns that were built to last for generations.

You can see it in the color and tone of the wood, the weathered patina that resulted from exposure to the elements - the harsh summer sun, lashing rain, and frigid snowstorms. They stood through it all. You can feel it as your fingers trace a groove worn smooth over years of use, or the roughened end grain of a wooden plug.

Maybe you can sense it when you glide your palm over granary planks polished satiny-smooth over the decades by tons of wheat, barley or corn. You can almost hear the rush of the tumbling grain. As your hand brushes over divots, dips and 3-dimensional grain lines you’ll wonder, what long-ago forces left their mark on this wood? Was it man, machine or beast?

Where some may see flaws, we see character. The beauty of our furniture is in its unique and wonderful imperfection.

Just like the barns from which the wood comes, Our furniture is crafted to stand the test of time. Our goal is for each table, hutch, bed and more to be enjoyed for generations to come.

Our hope is to be a part of your family’s history in the making.

Choose what wood you would like

We offer several different wood species in our reclaimed wood. You are not limited to just one wood species or just one look. The saw-marks and all the character you see in our furniture are real not the fake stuff you see today.

Douglas Fir

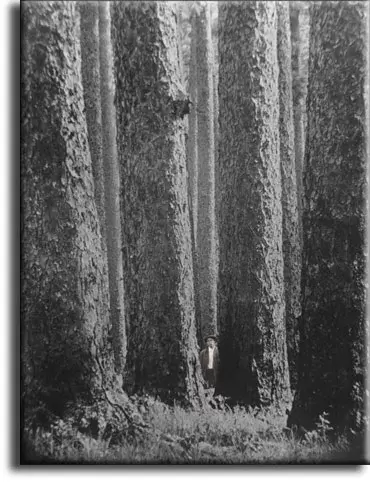

Most of our structures come from Oregon and they are built prior to 1925 so although Douglas Fir is a softer wood in today's generation old growth is harder than today's fast growing trees

According to popular myth, many mice hid inside the scales of the Douglas Fir tree's cones (see picture above), which was kind enough to offer sanctuary for them during forest fires. Each of the three sided bracts of the Douglas fir cone makes the tail and two tiny legs. Douglas fir trees are not a single species, as there are approximately 50 different species of Douglas firs that thrive throughout the Northern Hemisphere.

In the past, Native people of North America used Douglas Firs both for nourishment and medicinal purposes. Dried inner bark was ground into a nutritious meal during times when there was a lack of food. On hot sunny days, when conditions were right, crystals of sugar formed at the tips of the needles and around the branches. This rare treat was eaten raw or collected for future use in sweeting food.

The dried sap of the Douglas fir was used to cure cold symptoms and the sticky buds were chewed to relive mouth sores. Young Douglas fir needles are high in Vitamin C and they were used to treat scurvy. Lumps of hardened sap were chewed to keep boredom away and to whiten teeth. The bark was used to make canoes and the roots were corded to stitch canoes and baskets and was used to make fishing nets.

The name Douglas fir comes from a Scottish botanist, David Douglas, who first introduced the tree into cultivation in 1826.

According to popular myth, many mice hid inside the scales of the Douglas Fir tree's cones (see picture above), which was kind enough to offer sanctuary for them during forest fires. Each of the three sided bracts of the Douglas fir cone makes the tail and two tiny legs. Douglas fir trees are not a single species, as there are approximately 50 different species of Douglas firs that thrive throughout the Northern Hemisphere.

In the past, Native people of North America used Douglas Firs both for nourishment and medicinal purposes. Dried inner bark was ground into a nutritious meal during times when there was a lack of food. On hot sunny days, when conditions were right, crystals of sugar formed at the tips of the needles and around the branches. This rare treat was eaten raw or collected for future use in sweeting food.

The dried sap of the Douglas fir was used to cure cold symptoms and the sticky buds were chewed to relive mouth sores. Young Douglas fir needles are high in Vitamin C and they were used to treat scurvy. Lumps of hardened sap were chewed to keep boredom away and to whiten teeth. The bark was used to make canoes and the roots were corded to stitch canoes and baskets and was used to make fishing nets.

The name Douglas fir comes from a Scottish botanist, David Douglas, who first introduced the tree into cultivation in 1826.

Red Oak

The Northern red oak is the most prized of the red oak group for lumber, all of which is marketed as red oak regardless of the species of origin. It is not good for outdoor use due to its open capillaries. One can blow air through an end grain piece 10 inches long to make bubbles come out in a glass of water. The bark of the White Oak is dried and used in medical preparations. Oak bark is also rich in tannin, and is used by tanners for tanning leather. Acorns are used for making flour or roasted for acorn coffee. Oak galls were used for centuries as the main ingredient in manuscript ink, harvested at a specific time of year.

It also has very appealing grain markings, particularly when quartersawn. Wide, quarter-sawn boards of oak have been prized since the Middle Ages for use in interior paneling of prestigious buildings such as the debating chamber of the House of Commons in London, England, and in the construction of fine furniture. Oak wood, from Quercus robur and Quercus petraea, was used in Europe for the construction of ships, especially naval men of war, until the 19th century, and was the principal timber used in the construction of European timber-framed buildings. Today oak wood is still commonly used for furniture making, flooring and timber frame buildings. Barrels in which red wines, sherry, and spirits such as brandy, Scotch whisky and Bourbon whiskey are aged are made from European and American oak. The use of oak in wine can add many different dimensions to wine based on the type and style of the oak. Oak barrels, which may be charred before use, contribute to the color, taste, and aroma of the contents, imparting a desirable oaky vanillin flavor to these drinks.

It also has very appealing grain markings, particularly when quartersawn. Wide, quarter-sawn boards of oak have been prized since the Middle Ages for use in interior paneling of prestigious buildings such as the debating chamber of the House of Commons in London, England, and in the construction of fine furniture. Oak wood, from Quercus robur and Quercus petraea, was used in Europe for the construction of ships, especially naval men of war, until the 19th century, and was the principal timber used in the construction of European timber-framed buildings. Today oak wood is still commonly used for furniture making, flooring and timber frame buildings. Barrels in which red wines, sherry, and spirits such as brandy, Scotch whisky and Bourbon whiskey are aged are made from European and American oak. The use of oak in wine can add many different dimensions to wine based on the type and style of the oak. Oak barrels, which may be charred before use, contribute to the color, taste, and aroma of the contents, imparting a desirable oaky vanillin flavor to these drinks.

Historic Heartpine

https://www.youtube.com/watch?v=7PwFtb0ob6g

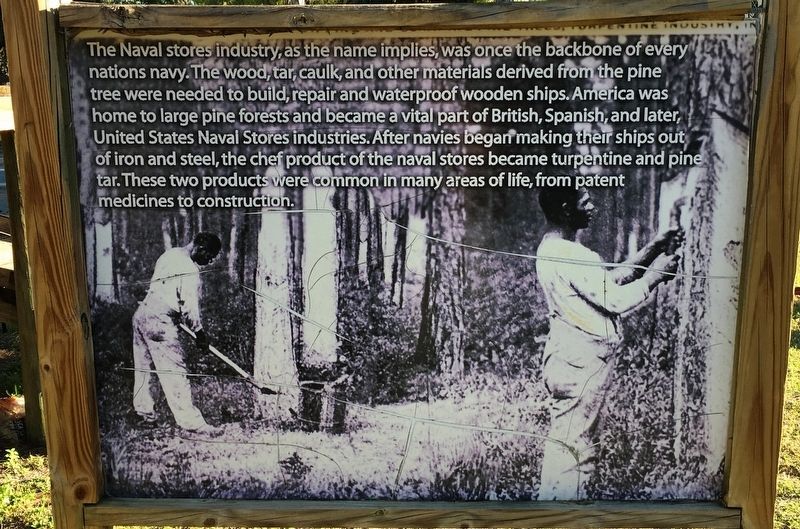

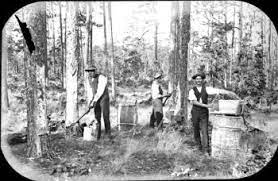

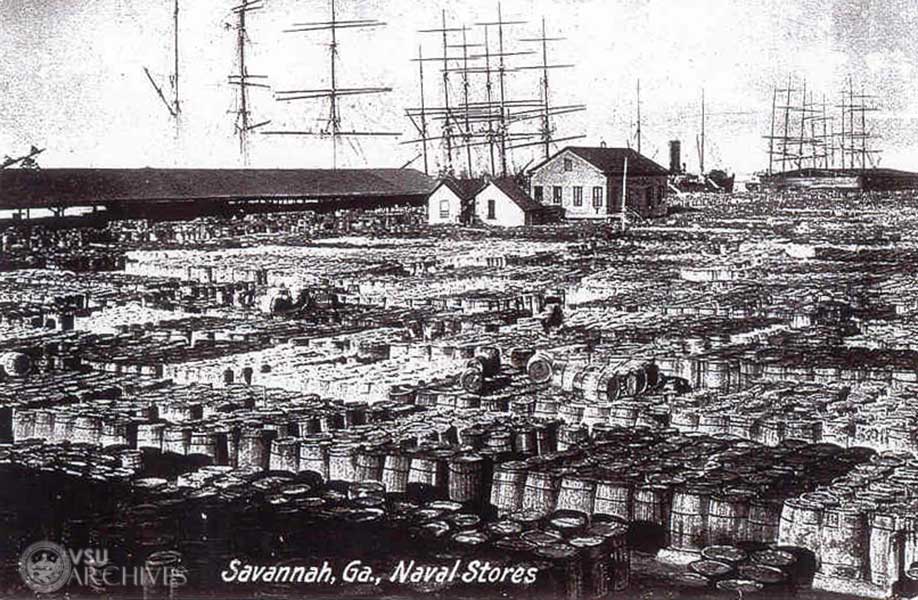

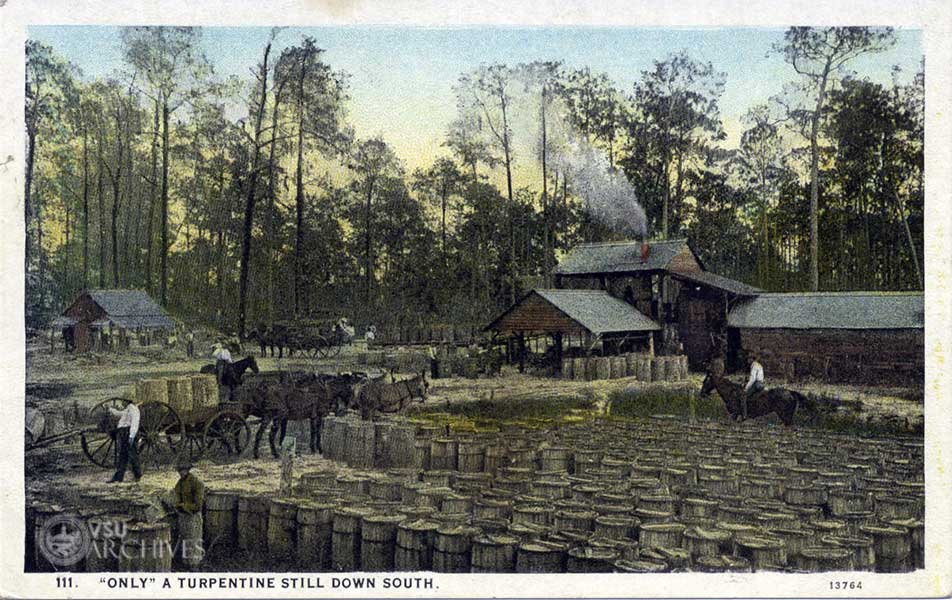

Thanks to Southern Longleaf pine, the United States was once the world leader in Naval supplies; tar, pitch and turpentine, until the mid 20th century. The bark was scraped with a *bark hack* to cause the tree to bleed oleoresin which was used to make turpentine. The injury to the tree caused it to produce denser growth and additional resin creating both harder and very beautiful wood. Over-logged and slow growing, the great Longleaf pine forests of the US have never returned . Longleaf pine has not been available commercially since 1924.

Heart Pine, also known as Southern Longleaf yellow pine, old growth pine or Heartpine served as a major factor in the building of much of colonial America. Colonists who set foot on this vast land found nearly 100,000 square miles of forests covering southwestern Virginia to central Florida, along the gulf coast as far west as Texas. These dense forests contained enormous trees that grew as tall as 175 feet and as wide as 125 inches. Most trees averaged 125 feet tall and 40 inches wide at maturity. The wood from these trees built a great number of structures throughout America and the world, many of which still stand today. Homes, plantations, mills, warehouses, factories and public buildings were constructed out of longleaf pine. In fact, the settlers of Georgia, Florida and the Carolinas built 75 percent of their houses and public buildings out of longleaf pine.

The astounding versatility of this wood was apparent, being incorporated into everyday items such as farm implements, furniture and cabinets, to construction, flooring and siding.; The exceptional structural quality of the longleaf pine was utilized in bridges, wharves, trestles, posts, joists and piles. The wood was used to build ships for first the English Navy, followed by the American Navy. Longleaf pine was also a major source for naval stores. The massive ship, the USS Constitution, also known as "Old Ironsides", was constructed using heart pine timber and white oak and its decks are of heart pine planks. This ship, built in 1794, is the oldest commissioned ship in the U.S. Navy.

Longleaf pine continued its historical impact with the ruling of King George II, who in the 1700's mandated that all straight pines exceeding 24 inches in diameter would be considered property of the crown. He then ordered his surveyors to brand the pines with his mark of a broad arrow. In response to this proclamation, the colonists tarred and feathered the surveyors. This act is considered by many to have been a precursor to the Boston Tea Party. As the Industrial Revolution surged ahead, the development of machinery and locomotives geared toward logging, and equipment such as steam skidders and band saws quickened the pace and greatly increased the volume of logs that was processed. By the mid-1920's, most of the available virgin forest was logged.

Sadly today, only about 5 percent of the original virgin forest remains. Longleaf pine was not replanted to a great extent, due to the lengthy period of time, 150 to 400 years, to maturity. The only sources of old growth heart pine available for use today are reclaimed wood from old buildings, or recovered wood from river bottoms.

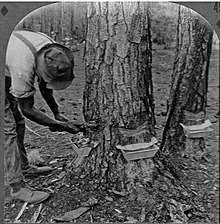

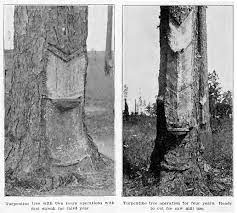

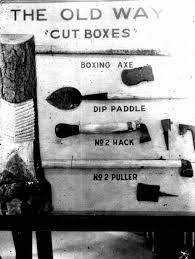

Obtaining Crude TurpentineRemoving resin (or crude turpentine) from longleaf pine was a laborious task. First a quart size hole, or “box,” was hollowed into each side of the tree about a foot from the ground.

Using a scraper, called a “hack”, a strip of bark was removed above the box. This strip, or “face”, was twelve inches wide and twenty inches long. Resin would seep from the trees, flow down the face and into the box. The box was emptied seven or eight times per year. This “dipping” of turpentine did not kill the tree since the resin is not part of the tree’s nutrient system. The face would be extended each season until it reached a height of about twenty feet. At that height the tree would cease to produce enough crude turpentine to be profitable.

Making Spirits of TurpentineOnce removed from the longleaf pine, kegs of crude turpentine were taken to distilleries, put into large copper kettles and brought to a boil. The resin would vaporize and condense in a cooling tower. The condensed liquid became the refined or “spirits” of turpentine Spirits of turpentine was used in paints and medicines, as a solvent, a fuel for lamps, and in processing rubber in the 1800s.

Heart Pine, also known as Southern Longleaf yellow pine, old growth pine or Heartpine served as a major factor in the building of much of colonial America. Colonists who set foot on this vast land found nearly 100,000 square miles of forests covering southwestern Virginia to central Florida, along the gulf coast as far west as Texas. These dense forests contained enormous trees that grew as tall as 175 feet and as wide as 125 inches. Most trees averaged 125 feet tall and 40 inches wide at maturity. The wood from these trees built a great number of structures throughout America and the world, many of which still stand today. Homes, plantations, mills, warehouses, factories and public buildings were constructed out of longleaf pine. In fact, the settlers of Georgia, Florida and the Carolinas built 75 percent of their houses and public buildings out of longleaf pine.

The astounding versatility of this wood was apparent, being incorporated into everyday items such as farm implements, furniture and cabinets, to construction, flooring and siding.; The exceptional structural quality of the longleaf pine was utilized in bridges, wharves, trestles, posts, joists and piles. The wood was used to build ships for first the English Navy, followed by the American Navy. Longleaf pine was also a major source for naval stores. The massive ship, the USS Constitution, also known as "Old Ironsides", was constructed using heart pine timber and white oak and its decks are of heart pine planks. This ship, built in 1794, is the oldest commissioned ship in the U.S. Navy.

Longleaf pine continued its historical impact with the ruling of King George II, who in the 1700's mandated that all straight pines exceeding 24 inches in diameter would be considered property of the crown. He then ordered his surveyors to brand the pines with his mark of a broad arrow. In response to this proclamation, the colonists tarred and feathered the surveyors. This act is considered by many to have been a precursor to the Boston Tea Party. As the Industrial Revolution surged ahead, the development of machinery and locomotives geared toward logging, and equipment such as steam skidders and band saws quickened the pace and greatly increased the volume of logs that was processed. By the mid-1920's, most of the available virgin forest was logged.

Sadly today, only about 5 percent of the original virgin forest remains. Longleaf pine was not replanted to a great extent, due to the lengthy period of time, 150 to 400 years, to maturity. The only sources of old growth heart pine available for use today are reclaimed wood from old buildings, or recovered wood from river bottoms.

Obtaining Crude TurpentineRemoving resin (or crude turpentine) from longleaf pine was a laborious task. First a quart size hole, or “box,” was hollowed into each side of the tree about a foot from the ground.

Using a scraper, called a “hack”, a strip of bark was removed above the box. This strip, or “face”, was twelve inches wide and twenty inches long. Resin would seep from the trees, flow down the face and into the box. The box was emptied seven or eight times per year. This “dipping” of turpentine did not kill the tree since the resin is not part of the tree’s nutrient system. The face would be extended each season until it reached a height of about twenty feet. At that height the tree would cease to produce enough crude turpentine to be profitable.

Making Spirits of TurpentineOnce removed from the longleaf pine, kegs of crude turpentine were taken to distilleries, put into large copper kettles and brought to a boil. The resin would vaporize and condense in a cooling tower. The condensed liquid became the refined or “spirits” of turpentine Spirits of turpentine was used in paints and medicines, as a solvent, a fuel for lamps, and in processing rubber in the 1800s.

Historic American Chestnut

There were once almost 4 million American Chestnut trees in the United States. They were among the largest, tallest and fastest growing trees in the eastern forest. The wood was long-lasting, straight grained and suitable for furniture, fencing and building. The nuts fed billions of birds and animals. It was almost a perfect tree-that is, until it was killed by a blight a century ago. That blight has been called the greatest ecological disaster to strike the world's forests in all of history. A tree that had survived all adversaries for 40 million years had disappeared in 10 years. What was once known as the queen of Eastern America, the American Chestnut is now nearly extinct.

The American chestnut was an economic staple of the original homesteaders in the Appalachian mountains. The wood was light weight , weather resistant, very easy to chop and mill by hand. Colonists used the trees not only for their homes but for fencing, rails and the nuts that they produced. They were known to grow up to 26" in diameter and if your farm had many American Chestnut trees you were considered to be a very wealthy farmer.

It is believed that in 1904 a forester from the Bronx Zoo brought in Asian Chestnut trees to decorate the Zoo. It was in these trees that a blight called Endothia Parasitica was born. The fungus, which was unintentionally brought to America, spread fast. In less than 10 years the American Chestnut was all but extinct. The root bases below the disease are still alive but the saplings that they produce do not live long. Researchers have spent the last 100 years trying to revive the species but to no avail. Our American Chestnuts are now gone.

The American chestnut was an economic staple of the original homesteaders in the Appalachian mountains. The wood was light weight , weather resistant, very easy to chop and mill by hand. Colonists used the trees not only for their homes but for fencing, rails and the nuts that they produced. They were known to grow up to 26" in diameter and if your farm had many American Chestnut trees you were considered to be a very wealthy farmer.

It is believed that in 1904 a forester from the Bronx Zoo brought in Asian Chestnut trees to decorate the Zoo. It was in these trees that a blight called Endothia Parasitica was born. The fungus, which was unintentionally brought to America, spread fast. In less than 10 years the American Chestnut was all but extinct. The root bases below the disease are still alive but the saplings that they produce do not live long. Researchers have spent the last 100 years trying to revive the species but to no avail. Our American Chestnuts are now gone.

Antique Pine

Our yellow pine comes from the East Coast. This wood is softer in nature but has a lot of character. This wood has been walked on for decades or it may have been the outside of the barn where it has aged through decades of storms. Usually has a lot of nail holes.

Order Process Reclaimed Wood

1. Wood Species

You choose the wood that you would like. While all of our woods are old growth and much stronger and more durable than today's woods, some are more dense than others.

Hardness Scale:

Antique Pine- One of our softer woods but has lots of character

American Chestnut- Denser than antique pine but can dent.

Douglas Fir- We use old growth Douglas Fir and the majority of our structures are constructed before 1925. Can dent but harder than today's fir.

Antique Heartpine and Old Red Oak- Very hard and durable does not dent very easy.

Hardness Scale:

Antique Pine- One of our softer woods but has lots of character

American Chestnut- Denser than antique pine but can dent.

Douglas Fir- We use old growth Douglas Fir and the majority of our structures are constructed before 1925. Can dent but harder than today's fir.

Antique Heartpine and Old Red Oak- Very hard and durable does not dent very easy.

2. Table Size

We offer any size that accommodates your needs. The easiest way that we have found is to place newspaper on the floor and allow 2' on each side of the table for your chairs with a minimum of 1.5'. We can build whatever size that looks comfortable for the room*.

***Our standard width is 36" but we can make the width wider or narrower to fit your needs. Our suggestion is to use the above method to measure. Round tables are available, but we cannot offer extensions on round tables.*

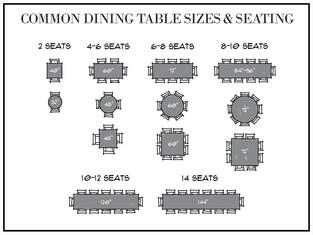

Below are some common seating arrangements: Please note that these may change according to your chair size and leg choice:

If rectangular, and the table length is:

3-4'- table Sits 4 comfortably.

5-foot table: sits 4-6 comfortably if it’s 5 feet round, up to 8 people comfortably.

6-foot Table: sits 6-8 comfortably.

7-foot table sits 8 very comfortably.

8-foot table: sits 8 very comfortably.

9 foot sits 10 comfortably.

10-foot table: sits 10 comfortably.

11-foot table: sits 10 very comfortably and 12 comfortably.

12-foot table: sits up to 12 very comfortably and up to 14 with narrower chairs.

13-foot table: sits 12-14 comfortably.

14–15-foot table: sits 14 very comfortably and 16 if need be.

16-foot table: sits 16 very comfortably and 18 if need be.

3. Top Thickness

You have the option of a thick or thin top. Our thin tops are generally 1" thick. Our thick tops are 1 1/2" . There is an extra charge for thick tops.

4. Company Boards

Extensions or leaves add length to a table when company arrives. *These are available on rectangular tables only*. Our extensions comprise of sliding dovetails that come out from the ends of the tables. This design does not compromise the stability of the table like tables with center leaves. Extensions add 18" to the overall length to each end adding a total of 3' to your table. Extensions can be added to one end as well instead of both. When not in use they can be stored in a closet. Drawers cannot be added to the table unless it is at least 7' in length due to the sliding dovetails. They are custom made so we cannot add extensions to an existing table or if you choose one extension we cannot go and add another one to the other end.

5. Rustic -Semi-Clean

Time worn wood is unparalleled in emanating its depth and nobility through the beauty of its patina. Patina can be described as a color ‘tarnish’ on wooden structures or items produced by age, wear, and exposure to natural elements; or any such acquired change of a surface texture and color through age and exposure.

Weathered wood achieves an enchanting patina over time. Older wood structures, furnishings and accessories may develop a hue or tone that speaks of many years of use and care. The natural aging process allows this patina to develop and will add even more of a sense of history and permanency to the treasured piece.

When patina is present on wood, there is no doubt that the presence of this colorful film is considered very desirable. This is due to the fact that the patina enhances the allure of the piece, while at the same time reminding people of the enduring nature that has remained around long enough to achieve the patina.

Patina is created by the natural maturing process. As the wood dries and ages, the oxidation occurring on the surface creates the patina. Many companies today try to replicate patinas on wood, but it is very difficult to fabricate in a day what nature takes many years to create.

We take this natural patina and we hand plane the surface. Our furniture is hand planed or hand scraped to give you a feel that only true craftsmen create.

Weathered wood achieves an enchanting patina over time. Older wood structures, furnishings and accessories may develop a hue or tone that speaks of many years of use and care. The natural aging process allows this patina to develop and will add even more of a sense of history and permanency to the treasured piece.

When patina is present on wood, there is no doubt that the presence of this colorful film is considered very desirable. This is due to the fact that the patina enhances the allure of the piece, while at the same time reminding people of the enduring nature that has remained around long enough to achieve the patina.

Patina is created by the natural maturing process. As the wood dries and ages, the oxidation occurring on the surface creates the patina. Many companies today try to replicate patinas on wood, but it is very difficult to fabricate in a day what nature takes many years to create.

We take this natural patina and we hand plane the surface. Our furniture is hand planed or hand scraped to give you a feel that only true craftsmen create.

6. Breadboard Ends:

A “breadboard end” is a narrow piece of wood that is mechanically joined to the end of a larger solid wooden panel—a table top, for example. Generally, the woodworker makes a “tenon”, or tongue, along the entire end of the panel and a matching groove along the entire length of the breadboard. They are joined together without glue, using instead wooden dowels this is a traditional and somewhat time-consuming joinery technique seen on the best quality furniture. All of our trestle tables come with breadboard ends.

7. Spoke Shaved edge vs. Machine Edge

A spoke shaved edge is where we take an old fashioned draw knife and shave down the edges to give it a more worn, softer look and is most popular with our customers. A routered edge is done by a machine and is used on fancier type tables. It is seen on a lot of production type tables.

8. Separate Board Look

This is an option that we offer that makes a tiny v-grove on the top of each board. This details shows the width of each board.

9. Drawer:

Drawers are hand cut dovetails. Size varies to accommodate the furniture.

10. Leg Choice

There are several different style legs that are available. Click on the picture to get a description.

11. Nail Holes

Our recycled wood that comes from old structures will have nail holes. It is your option to leave those open or we can fill the holes.

12. Payment:

We take all forms of payment. Credit card numbers are not kept and are destroyed after using. We require half down and the balance upon completion.

13. Shipping:

We have an awesome shipping company, and we can get you reasonable rates. Our furniture is shipped in a plywood crate. There will be a 100.00 crate fee to cover the cost of the materials. We ship all over the world.

We take all forms of payment. Credit card numbers are not kept and are destroyed after using. We require half down and the balance upon completion.

13. Shipping:

We have an awesome shipping company, and we can get you reasonable rates. Our furniture is shipped in a plywood crate. There will be a 100.00 crate fee to cover the cost of the materials. We ship all over the world.

Location263 Silverbrook Rd

Randle’, WA 98377 (509) 985-6844 |